EVO_heat

Protective covers resistant to heat radiation and to splatter from hot particles

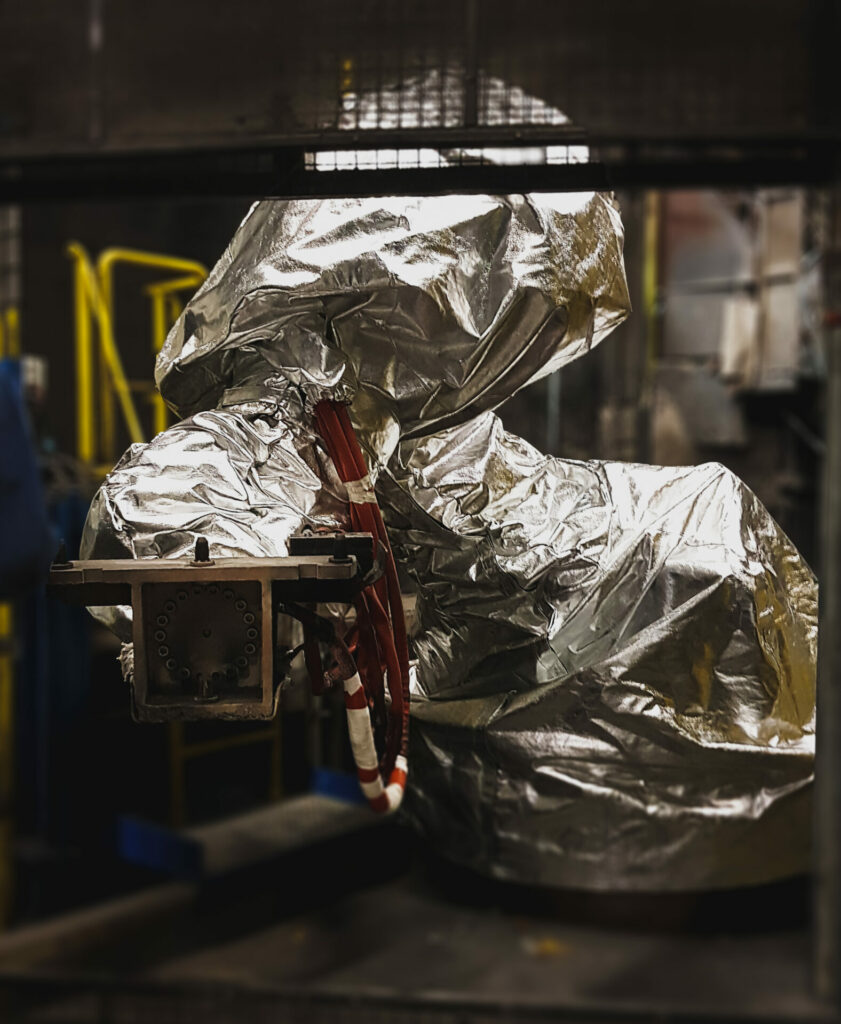

Robot covers for radiant heat protection.

EVO_heat protective covers can be used in foundries, as well as processes involving high temperature, such as welding, hot forging, die casting or hardening.

The purpose of this type of cover is to protect the robot from sparks and hot metal spatter, as well as from harmful effects of heat radiation.

EVO_heat robot cover also protect from dust generated e.g. in the process of scale removal from hot parts.

Robots heat protection in high temperature processes.

EVO_heat covers protect from harmful conditions such as:

- Radiant heat

- Spatter of hot solid particles

- Sparks

- Dust

These factors are present in the processes:

-

![]() Metal casting

Metal casting

-

![]() Laser cutting

Laser cutting

-

![]() Metal punching

Metal punching

-

![]() Welding

Welding

-

![]() Soldering

Soldering

-

![]() HVOF

HVOF

-

![]() Plasma cutting

Plasma cutting

-

![]() Pick&place of hot parts

Pick&place of hot parts

-

![]() Hot forging

Hot forging

-

![]() HPDC

HPDC

Comprehensive perfection of your EVO_heat cover.

EVO_heat protective covers are made of non-flammable fabrics, often with a reflective coating.

Covers for special purposes.

Specially chosen technology of connecting cover parts.

The thread and other connecting elements are chosen depending on the fabric and the process in which the robot is working, which prevents contaminants from getting under the cover. This enables the cover to protect the machine from factors that could cause damage or a malfunction. A reflective coating reflects part of radiant heat which often is generated in production processes, e.g. by furnaces. Thanks to this feature, EVO_heat can protect the robots from the effects of overheating.

In some cases we recommend making rotary rings, as an integral part of the cover, which increases the protection level. Thanks to this kind of solution we increase the freedom of movement and additionally protect the base of the robot.

Let’s talk about what harmful factors your robot is exposed to.

Book a conversation now.

-

1

together we will determine

what you need -

2

you receive

a personalized offer -

3

we provide

an effective solution