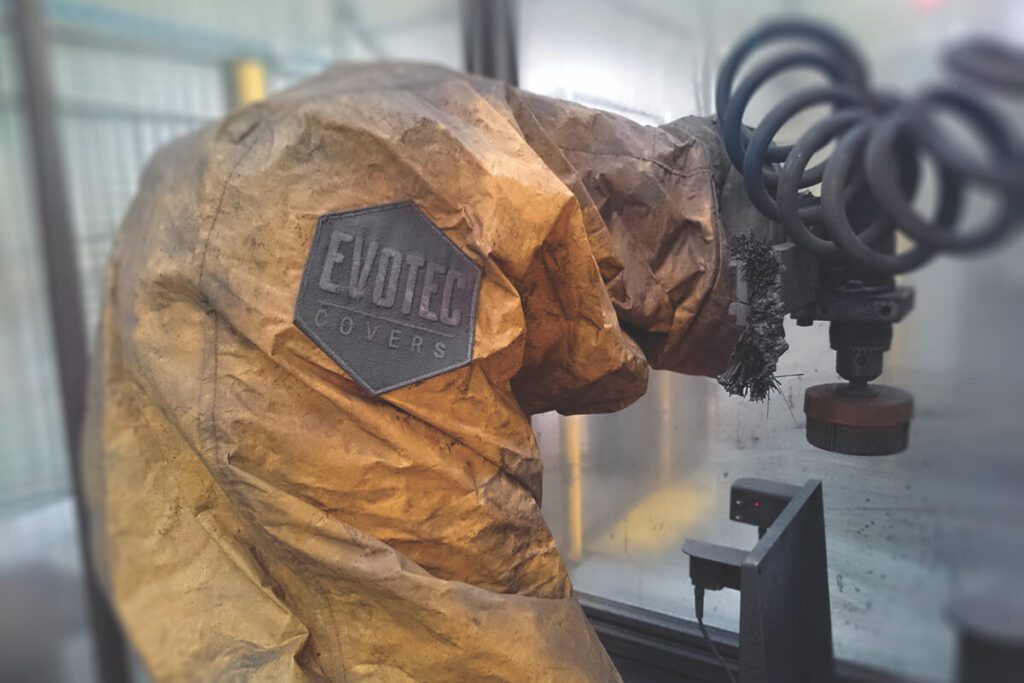

EVO_blast protective covers to protect FANUC M710iC robots working with metal part shot blasting

Have any questions? Write to us and

we'll get back to you.

Let's talk about the best solution for you.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution

CLIENT

A Polish company producing and machining parts made of aluminium, cast iron, steel and other materials.

Aluminium part deburring is a process of removal of sharp, uneven ridges from the surface and edges of the machined part. In this case it is done with a special brush. Using this tool, the robot cleans and smooths the surface of the part.

Very fine dust and metal shavings accumulate on the surface of FANUC LR MATE 200iD robot and inside the moving parts such as gears and servo drives, which could cause malfunctions. What is more, the robot is working inside an explosion risk zone. Since aluminium dust can be explosive, if a spark appeared inside the chamber, it would cause ignition and consequently – an explosion.

The EVO_dust robot cover is meant to protect the machine from fine dust getting inside its moving parts, which protects it from damage and from aluminium shavings accumulating on its surface.

Since the robot is working inside an explosion risk zone, the cover was made from fabric with anti-static properties. The smooth surface of the cover prevents accumulation of dust and other contaminants, as well as reduces the risk of an electric charge, which can be particularly dangerous in environment with explosive dust.

Let’s talk about what harmful factors your robot is exposed to.

Book a conversation now.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution