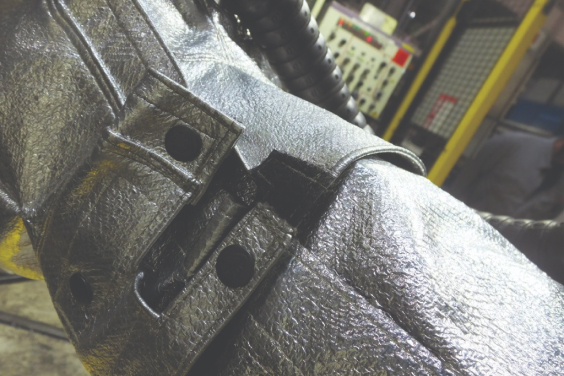

EVO_blast protective covers to protect FANUC M710iC robots working with metal part shot blasting

Have any questions? Write to us and

we'll get back to you.

Let's talk about the best solution for you.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution

THE CLIENT

is an international Automotive concern manufacturing cars with both exhaust and electrical engines.

The main risk to the FANUC R1000 industrial robot is radiant heat. Due to close proximity of the robot to the induction furnace, the temperature in the area often exceeds the upper permitted limit. This may cause the servomotors to overheat and require downtime. Using a robot in these conditions could have a negative impact on production continuity, which in a large factory like this results in delays and financial loss.

The purpose of the EVO_heat protective cover is protection of the robot from radiant heat. The cover consists of three parts fitted to its construction, which cover the entire surface of the robot and part of the gripper, shielding it from radiant heat.

The cover is made of Aramid fabric with a reflective coating. The base of the fabric is a polymer with high mechanical resistance. It provides durability of the fabric during the robot’s work. The coating of the fabric reflects up to 90% of radiant heat, which greatly slows down the heating up of the robot, compared to work without any cover.

Thanks to the EVO_heat protective cover for FANUC R1000 robot, the risk of malfunction is decreased, which ensures process continuity and protects the robot mechanisms from overheat

Let’s talk about what harmful factors your robot is exposed to.

Book a conversation now.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution