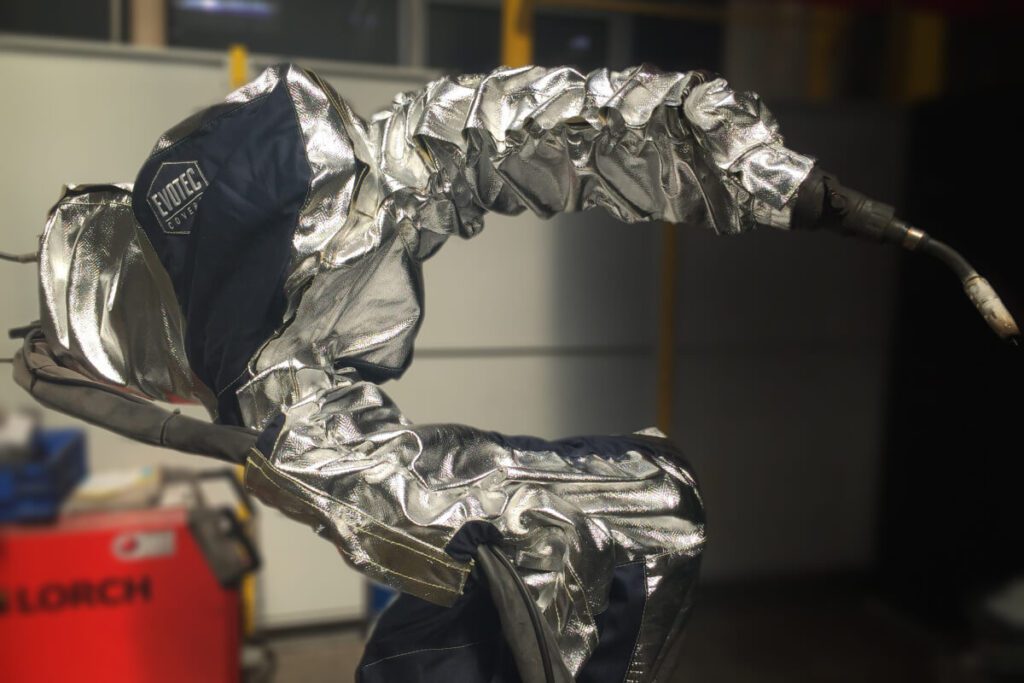

EVO_blast protective covers to protect FANUC M710iC robots working with metal part shot blasting

Have any questions? Write to us and

we'll get back to you.

Let's talk about the best solution for you.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution

THE CLIENT

One of the world leaders in agricultural vehicle production.

Industrial robots working with welding are exposed to spatter, sparks and dust which penetrates their gears, causing them to loosen. This generates expenses related to additional downtime for repairs, as well as replacement of gears, which are some of the most expensive parts of industrial robots. The dust generated in the process settles on the robots which require frequent cleaning.

The EVO_heat protective covers are made of non-flammable fabrics resistant to temperature of up to 250°C. The coating of the fabrics used in the covers is also an impenetrable barrier to dust, which would have otherwise accumulated on the robot.

We made protective covers with light construction, which protects ABB and Yaskawa Motoman robots from harmful effects of factors such as sparks, spatter or dust, protecting both the surface of the robot and its mechanical parts such as gears.

Let’s talk about what harmful factors your robot is exposed to.

Book a conversation now.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution