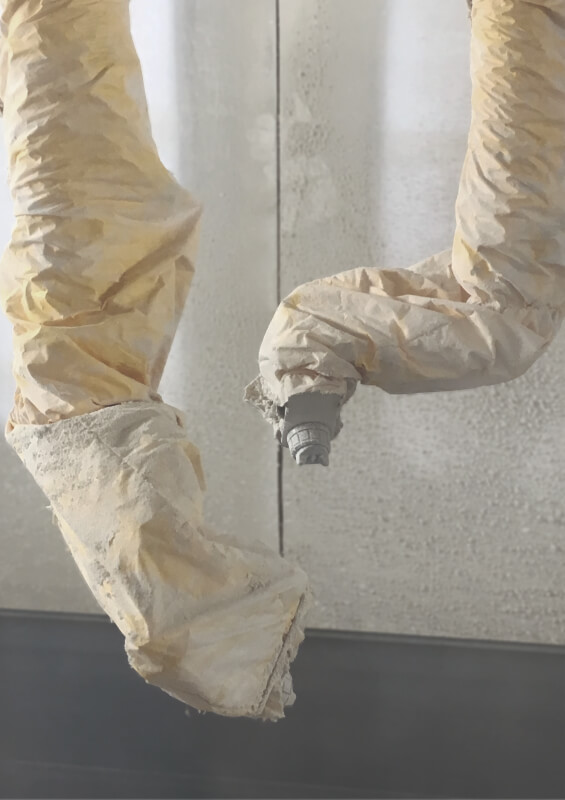

EVO_blast protective covers to protect FANUC M710iC robots working with metal part shot blasting

Have any questions? Write to us and

we'll get back to you.

Let's talk about the best solution for you.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution

THE CLIENT

is a global leader in window frames production.

Powder coating involves paint in the form of powder which accumulates on surfaces and gets inside the moving parts of the robot. This causes accelerated degradation of the robot surface and gear seizing, which results in additional unplanned downtime and expense.

Another consequence of a large amount of contaminants accumulating on the coating tool is contamination of the painted parts when pieces of paint fall of the machine. This also causes financial loss. Additionally, the powder coating area is an explosion risk zone.

The EVO_coat protective cover is made of light, dustproof fabric, which prevents particles of paint from entering the robot gears and accumulating on the surface. Since the covers can be replaced as needed, there is no excessive accumulation of paint on the cover, which makes the workpieces safe from falling flakes of paint. Using a cover greatly reduces the time needed for cleaning the robot.

The fabric used for making the EVO_coat cover has a special coat with anti-static properties. Thanks to this feature, the cover can support the work of the robot in an explosion risk zone. However, using a cover does not automatically protect the workstation from explosion risk – this kind of assessment should always be done by qualified specialized units.

Let’s talk about what harmful factors your robot is exposed to.

Book a conversation now.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution