EVO_blast protective covers to protect FANUC M710iC robots working with metal part shot blasting

Find the solution

We will provide you with a tailor-made solution for your needs. Leave your contact details and we will get back to you within 24 hours.

THE CLIENT

is a Polish glassmaking factory producing glass for uses such as household, protective shielding, technical uses, as well as stained-glass window glass and coloured glass used in signalling in transport: railway, car, sea and aviation.

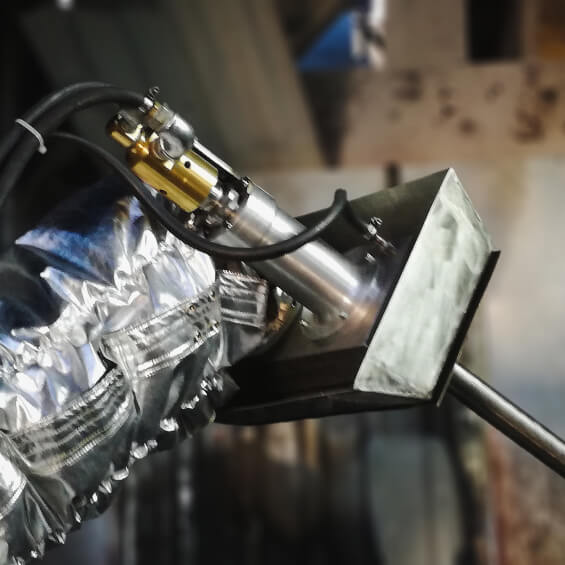

The Kawasaki RS050 robot picks up gobs of molten glass from a furnace. Therefore it must be placed near the hot furnace opening. The main harmful factors in the process are: radiant heat, hot splashes and hot dust generated in the process. In this case, the protective cover is necessary for safe work of the robot.

The EVO_heat protective cover for KAWASAKI RS050 robot is made of technical fabric with reflective properties, which enable it to reflect up to 90% of emitted radiant heat. The fabric is also non-flammable and resistant to hot splashes. Thanks to the cover, the surface of the robot and its additional equipment is well separated from harmful factors in the robot environment.

Since the robot is located very close to the furnace, the EVOTEC protective cover made of technical fabric was integrated with metal elements, which further insulated the robot from radiant heat. Between the robot flange and wrist there was a metal insulation shield installed, which reduced the overheating of the axis 6, stopping part of the heat transferred through the tool.

The Client also introduced cooled air under the EVO_heat cover. There were temperature sensors installed on the robotic axes. When the working temperature of servomotors reached the upper limit, it was possible to stop the robot to avoid a malfunction. This solution enabled the Client to continuously monitor the work of the KAWASAKI RS050 robot despite the extreme conditions.

Let’s talk about what harmful factors your robot is exposed to.

Book a conversation now.