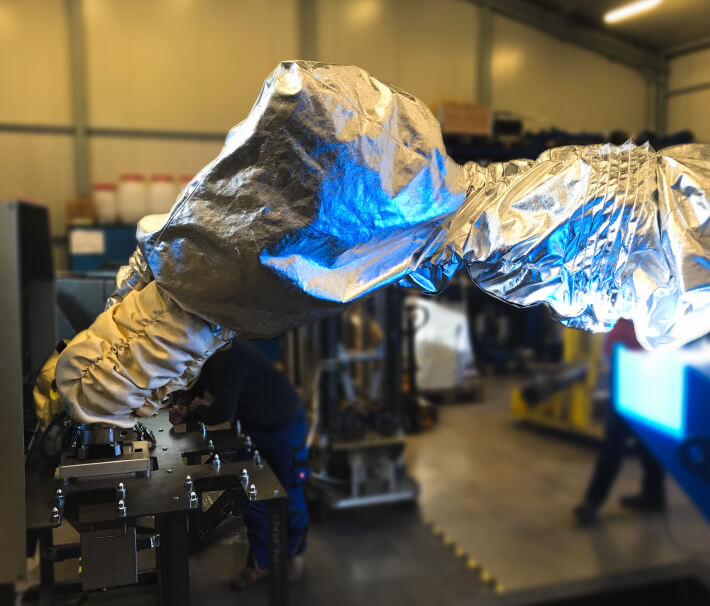

EVO_blast protective covers to protect FANUC M710iC robots working with metal part shot blasting

Have any questions? Write to us and

we'll get back to you.

Let's talk about the best solution for you.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution

THE CLIENT

A globally active European company working with integration of robotic industrial production lines

The most important risk to the work of KUKA robot is very high heat radiation generated by the steel melting furnace. The radiation temperature would reach even 1500°C, which meant that the robot’s working temperature was much higher than the permitted limit. Without a cooling system, the robot located 3 metres from the furnace would not be able to work at all. Work in such high temperature could cause overheating of servomotors and an uncontrolled break in the process.

What is more, in the steel casting process there are hot particles splashes and a large amount of dust present, which could have a destructive effect on the robot surface and the equipment. The dust is abrasive, so when it gets inside the gears of the robot it causes damage and a malfunction of the entire robot, which makes it necessary to replace the part.

The solution is a protective cover for KUKA KR210 robot, made of non-flammable technical fabric coated with a special layer reflecting radiant heat and resistant to splashes of solid particles.

Because of high temperature heat radiation, the most vulnerable spots on the robots are protected with an additional replaceable cover that is put on top on the main cover, on the upper arm of the robot.

All cables and conduits supplying cooled air to the robot wrist, and even the metal shield on the wrist, are also protected with fabric resistant to very high temperatures. Otherwise, they could become damaged by contact with hot splashes.

Using the EVO_heat protective cover in the hot metal sampling process ensures continuity of the production process and decreases the risk of a malfunction. This solution also decreases the operative cost of the industrial robot.

Let’s talk about what harmful factors your robot is exposed to.

Book a conversation now.

together we will determine

what you need

you receive

a personalized offer

we provide

an effective solution